FDM

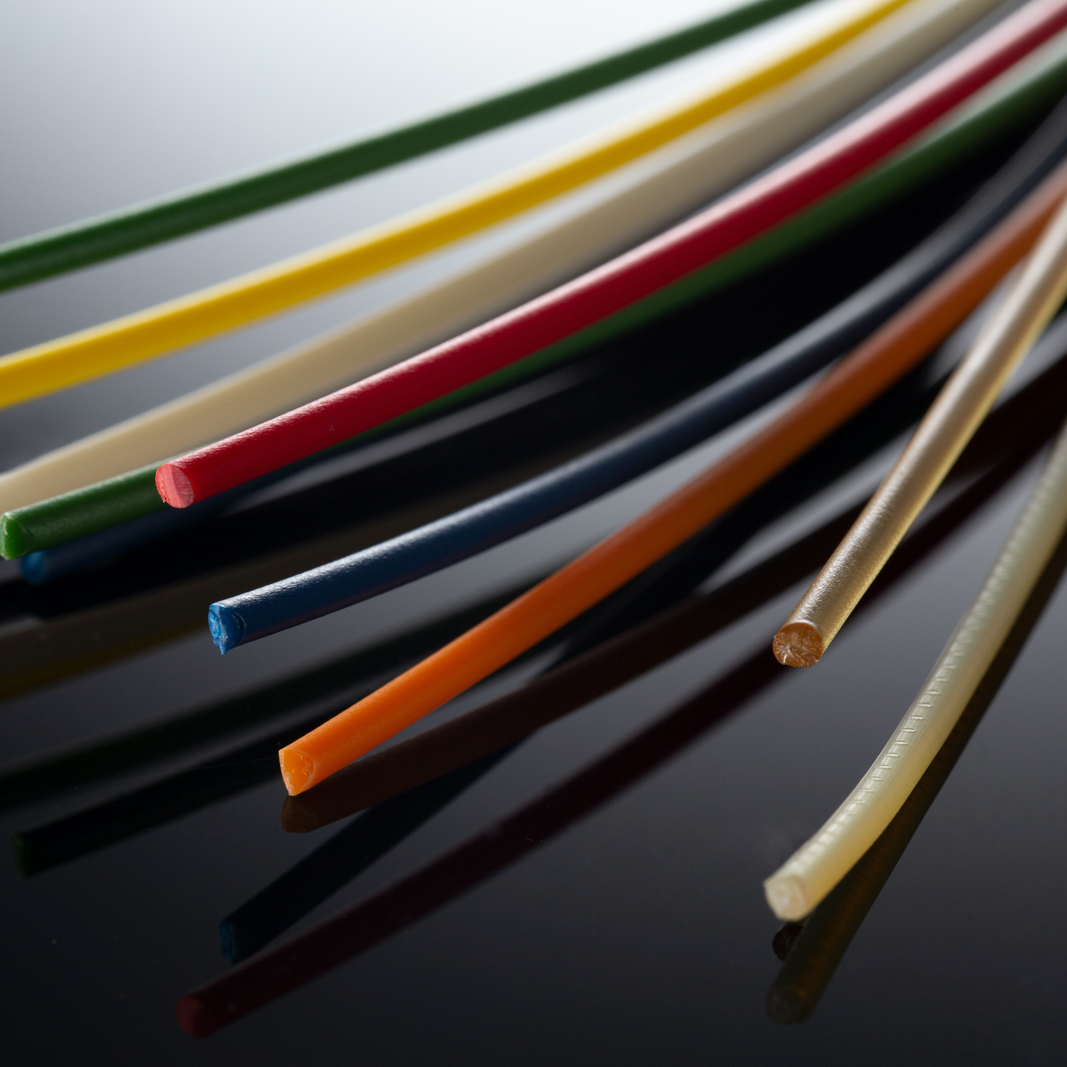

FDM (Fused Deposition Modeling) is one of the oldest 3D printing techniques. Thermoplastic material, in the form of filament, is melted in an extruder, deposited precisely in place via a nozzle and thus the workpiece is built up layer by layer. This is done with a dimensional accuracy of 0.1 mm and high repeat accuracy. Overhanging parts can be printed with support material. The (water-soluble) support is removed afterwards.

The largest FDM printer at SEIDO Solutions has a build volume of up to 914 x 610 x 914 mm. Because this technology has been used in multiple industries for several decades, a wide range of thermoplastics are available. These range from ABS, ASA and Polycarbonate to engineering plastics such as Ultem and Antero, which can be used, for example, to print parts for under the hood of a sports car or certified aircraft parts.

Quality & confidentiality

All parts are produced in-house on high-quality production equipment!

Speed

Efficient workflow ensures short delivery times.

Large production capacity is available.

Personal contact & Advice

We are happy to help you choose the technology and material that is best suited for your application.