SLM

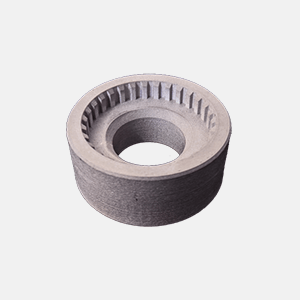

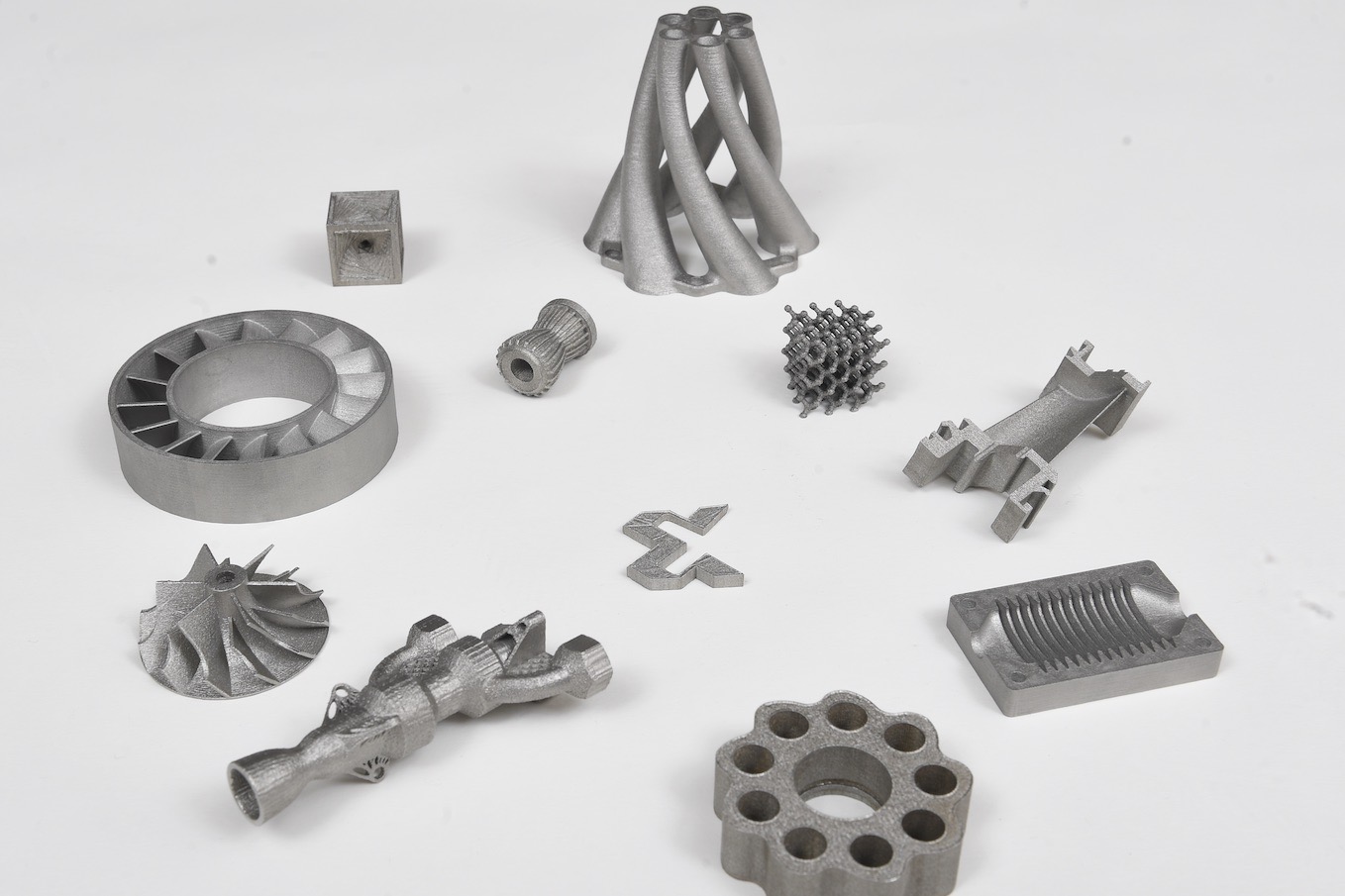

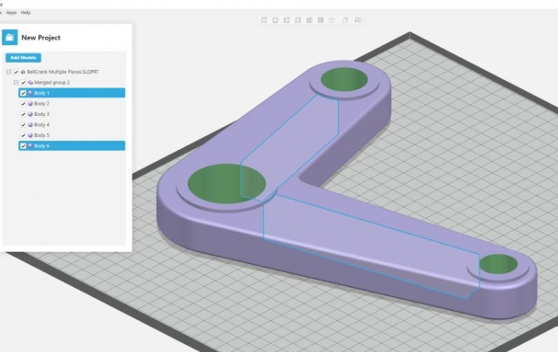

In the metalworking industry, series are getting smaller and smaller. This means that the setup cost per part is increasing. By producing parts with 3D metal printing, numbers play less of a role. Moreover, no tools, such as fixture jigs, are required, which means production on a 3D metal printer can be started immediately. SEIDO Solutions uses laser powder bed fusion technology: the laser exposes a layer of metal powder. The energy of the laser beam "welds" the powder to the adjacent powder particle, thus building up the metal part layer by layer. This can be done up to a size of 150 x 150 x 150 mm; complex shapes, such as integrated cooling channels, are no problem. We also have the ability to post-mill parts to achieve requested tolerances.

Maximale bouwgrootte

L 150 x B 150 x H 150mm

Nauwkeurigheden

IT14

Quality & confidentiality

All parts are produced in-house on high-quality production equipment!

Speed

Efficient workflow ensures short delivery times.

Large production capacity is available.

Personal contact & Advice

We are happy to help you choose the technology and material that is best suited for your application.