Jig & Fixtures

Jigs & Fixtures

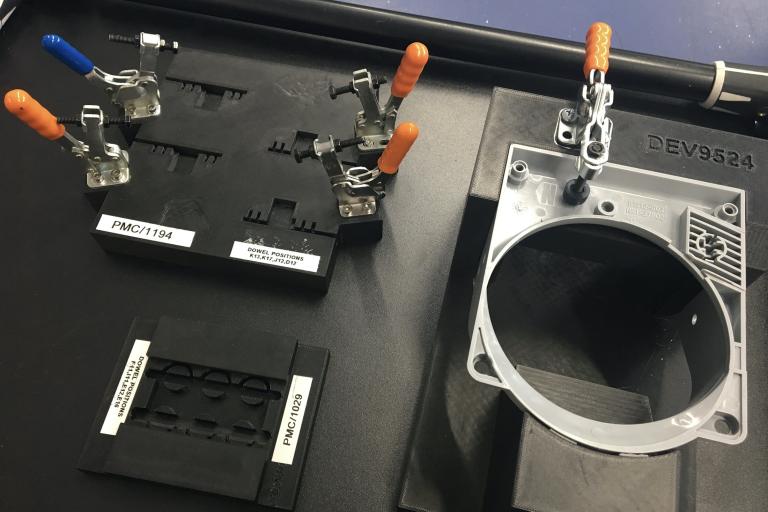

Producing custom molds and fixtures can be done easily, quickly and cost-effectively on-site with 3D printing

Why use 3D-printing for Jig & Fixtures?

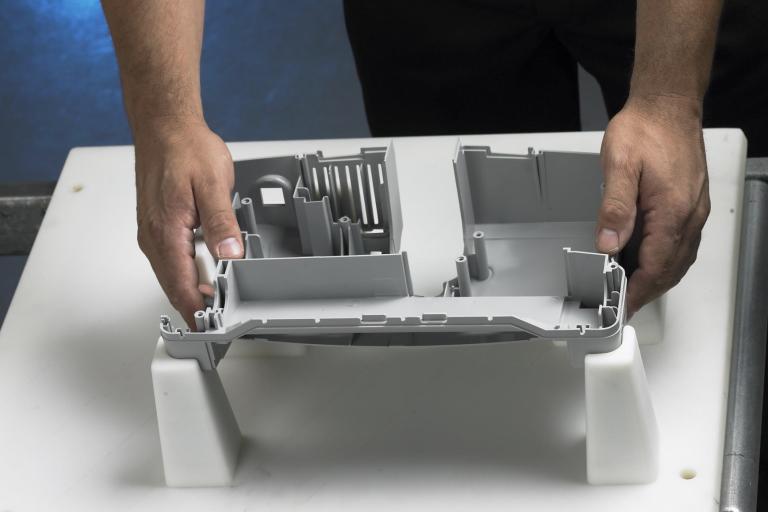

To maintain quality, efficiency and safety, companies rely on custom molds and fixtures to position, protect,... parts at all stages of the manufacturing process.

3D printing can significantly improve the production of these tools and fixtures, eliminating cost and design barriers.

- FDM 3D printing technology builds plastic parts, layer by layer, directly from CAD files. This simplifies the entire process, it is cost-effective and less time-consuming

- Evaluate and make immediate improvements to the model

- FDM allows tools to be made for optimal performance and ergonomics

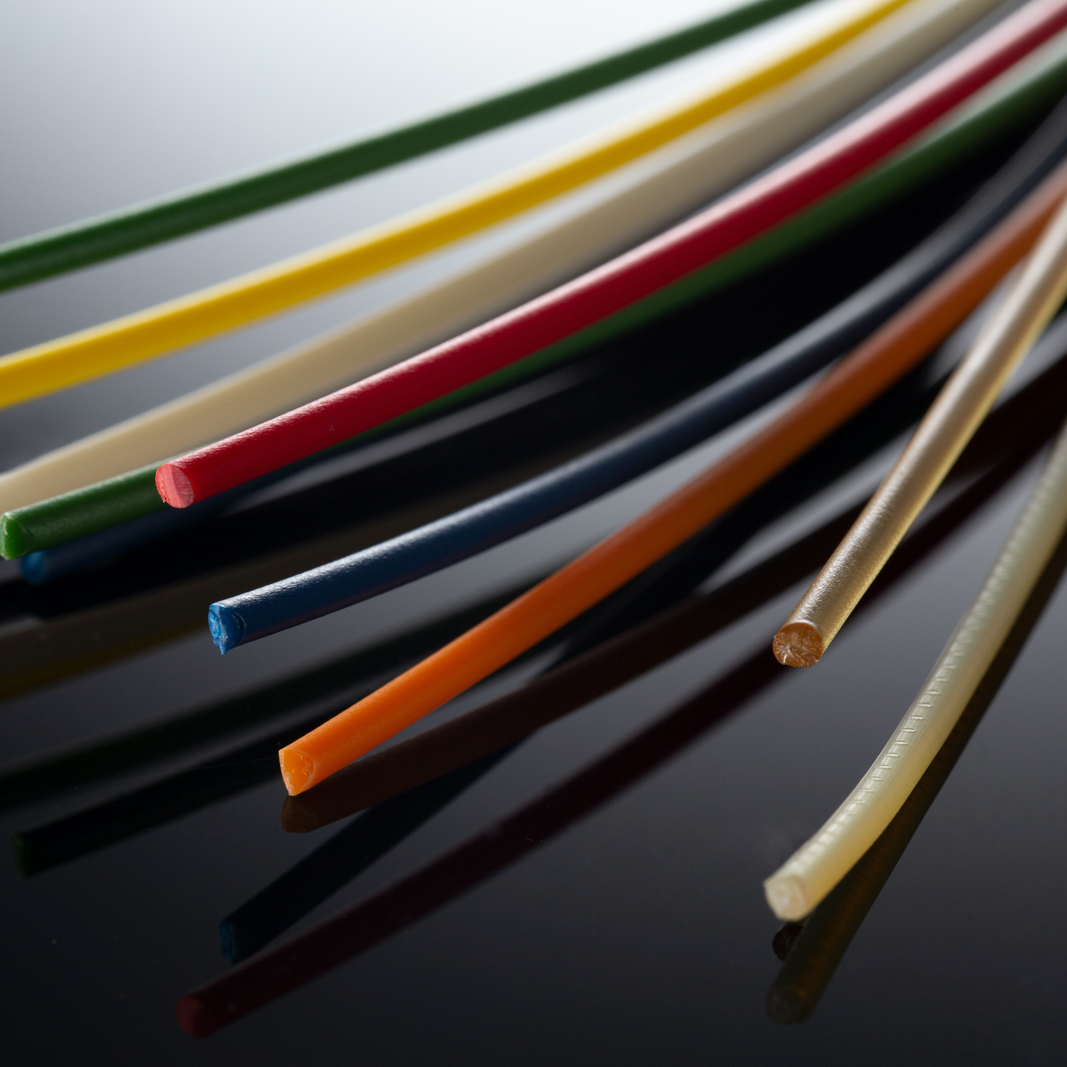

- Molds and fixtures made of durable thermoplastics are strong, lightweight and able to withstand harsh manufacturing environments

- Biocompatible materials are ideal for the medical industry

- The multi-materials of PolyJet technology make it possible to create customized molds and fixtures to suit individual needs

Case Studies

Quality & confidentiality

All parts are produced in-house on high-quality production equipment!

Speed

Efficient workflow ensures short delivery times.

Large production capacity is available.

Personal contact & Advice

We are happy to help you choose the technology and material that is best suited for your application.